- Product Details

-

Custom Style Prefabricated Building House

The main body of this villa is in light brown color, which contrasts with the dark brown roof and window frames, showing an air of stability and elegance. The window design is simple and generous, and each window is matched with a white window frame, which increases indoor lighting and enhances the overall aesthetics. Heavy steel structure is adopted as the main frame, which is characterized by high strength, good stability and superior seismic performance. At the same time, the construction cycle of heavy steel structure villa is short, easy to assemble, and green, which meets the modern demand for high-quality housing.

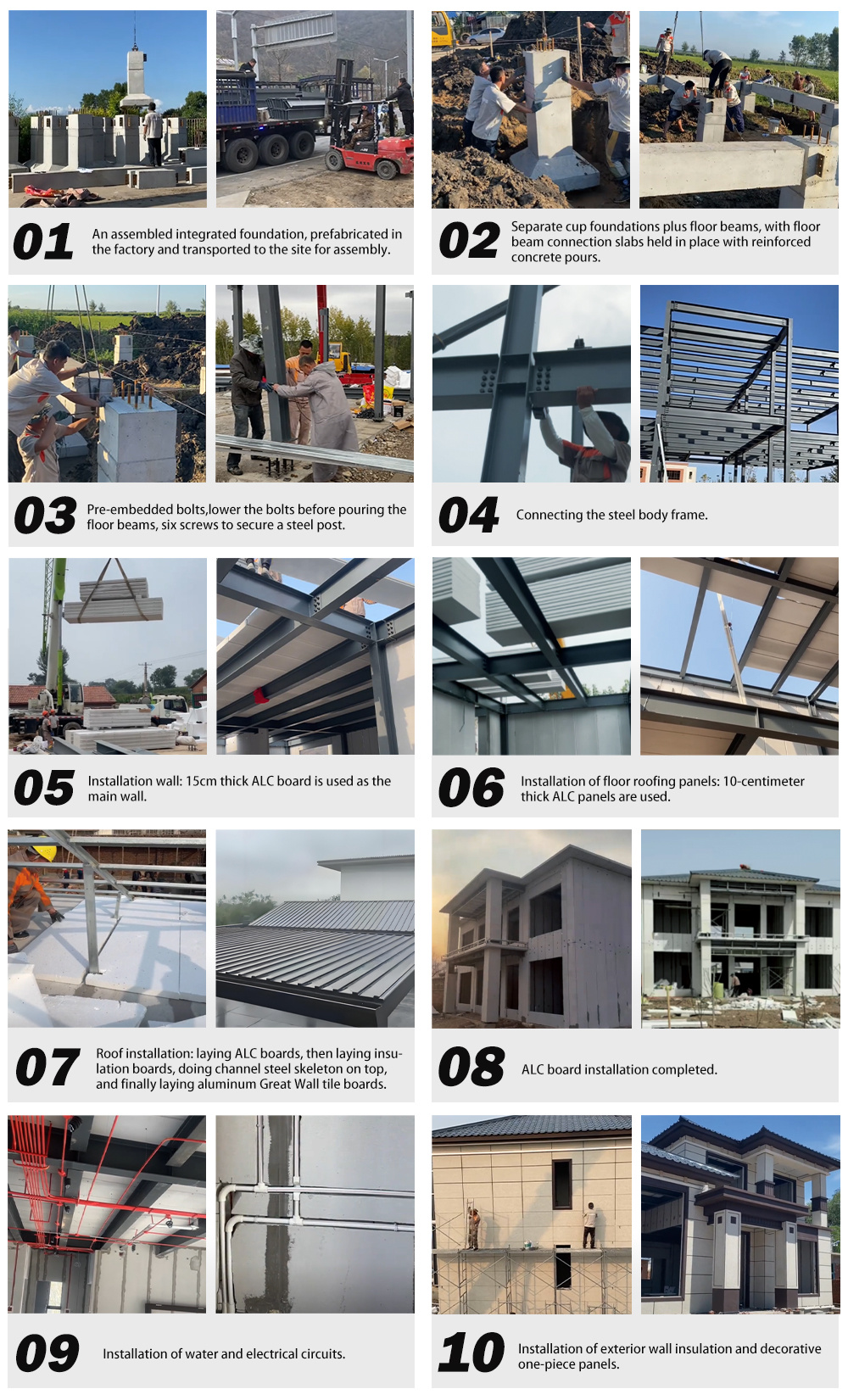

Technological Process

1、An assembled integrated foundation, prefabricated in the factory and transported to the site for assembly.

2、Ground foundation.Independent cup foundations with ground beams, where the connecting plates of the ground beams are poured with reinforced concrete. The ground beams can be suspended, and the backfill soil is compacted. Alternatively, the entire structure can be poured with reinforced concrete.

3、Before pouring the ground beam, the embedded bolts should be installed. Six bolts are used to secure one steel column. By tightening the first nut, the bolts on top of each cup foundation are adjusted to the same horizontal level, and then a gasket is placed underneath. The steel column is connected to the foundation as a whole through anchor bolts.

4、The steel frame is connected by utilizing high-strength bolts (Grade 10.9) instead of traditional welding techniques between steel beams and steel columns. All structural joints are connected exclusively with high-strength bolts.

5、Installation of Walls: 15cm thick ALC (Autoclaved Lightweight Concrete) panels are used as the main wall material. ALC panels can be cut, planed, drilled, grooved, and even reamed (being made of inorganic silicate materials). They are connected to the steel structure as a whole through hook-head bolts. One end of the bolt has a hook that fits onto the steel beam, while the other end is secured with a washer and a nut.

6、For the installation of floor and roof panels, 10cm thick ALC (Autoclaved Lightweight Concrete) panels are used, which are laid flat on our platform beams. (The load capacity per square meter reaches 5 kN, and ALC panels are also adopted for wall maintenance and floor panels.)

The main raw materials of ALC (Autoclaved Lightweight Concrete) panels are lime, cement, and silica sand. They contain a double-layer, bidirectional steel mesh inside. The sound insulation capability reaches 40.8 dB, the single-point hanging capacity achieves 1200 N, the compressive strength attains 5.0 MPa, and the thermal conductivity coefficient is 0.13.

7、Installation of Roof: The roof adopts a design with one room having two layers. Firstly, ALC (Autoclaved Lightweight Concrete) panels are laid flat. Then, insulation boards are installed on top. Steel channel framing is constructed above the insulation boards, and aluminum Great Wall-style large roof tiles are laid on top of the steel channel framing.

8、Installation of ALC Panels Completed.

9、Installation of Water and Electrical Circuits.

10、For the installation of exterior wall panels, the joint seams of ALC (Autoclaved Lightweight Concrete) wall panels are filled with crack-resistant mortar. The exterior walls employ an integrated insulation and decoration panel fixed to the ALC panel's outer wall through a combination of point adhesive mortar and fasteners. This forms the insulation layer and decorative surface of the exterior wall.

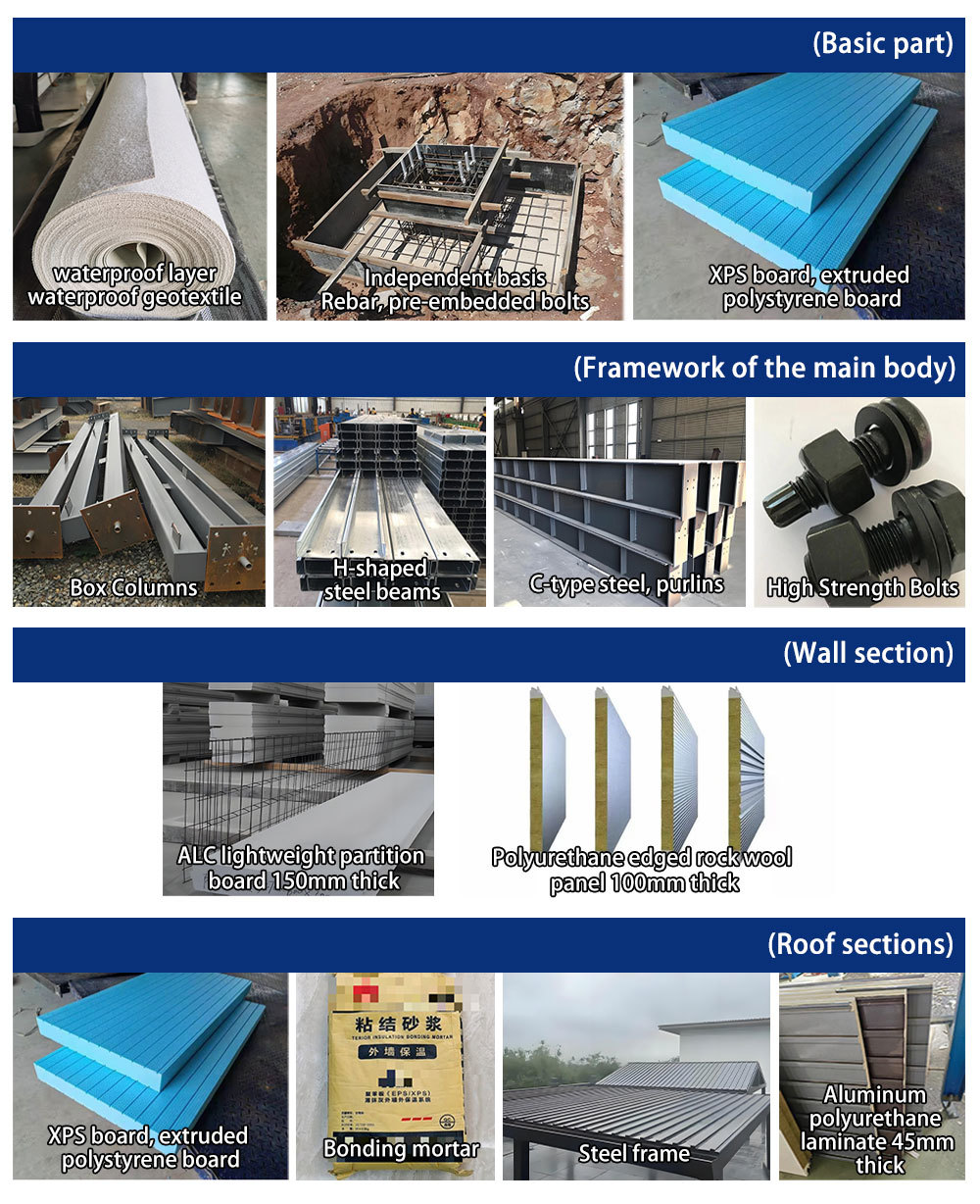

Material of construction

Customize the interior style

Parameter Table

Title constituent part base component waterproofer Waterproof geotextile single footing Threaded steel bars, embedded bolts Bottom insulation XPS board, extruded polystyrene board Main steel frames Steel structure part Box type post H-shaped steel beam C type steel purlin high-strength bolt structure Wall section ALC Lightweight partition board 150mm thick Polyurethane edged rock wool panel 100mm thick Roof section ALC Lightweight partition board 150mm thick XPS board, extruded polystyrene board Bonding mortar Steel frame Aluminum polyurethane laminate 45mm thick ground ground ALC slab Tile floor interior finish wall carbon crystal plate great wall panel suspended ceiling light steel keel bamboo and wood fiber doors and windows door Interior suite door entry door Windows Broken bridge aluminum window waterway waterproof material Water supply pipe ppr Drainage pipe PVC thermal insulation material Electric distribution light socket mains switch electric wire distribution control box parts Sealant, self-tapping screw, ordinary screw Product Advantage

1、Main frame: adopts heavy steel structure, which is solid and stable, with strong load-bearing capacity.

2、Wall part: composite lightweight partition wall system, composed of 150mm thick ALC lightweight partition wall panels and 100mm thick polyurethane edged rock wool panels; ALC panels provide thermal insulation, sound insulation, fireproofing, seepage resistance, and can reduce the self-weight of the building; polyurethane edged rock wool panels have a high fire-resistant inorganic fiber core, and the edges are sealed to enhance the integrality and waterproofing, which work together to create a high-performance composite wall.

3、Roof part: steel-aluminum composite roofing system, steel frame load-bearing, 45mm-thick aluminum polyurethane composite panels for maintenance panels, surface layer of aluminum corrosion-resistant, decorative, polyurethane core material with excellent thermal insulation. XPS board insulation layer is also set up, which has low thermal conductivity and high compressive strength, and enhances the thermal insulation and energy saving of the roof.

4、Ground part: ALC board is used as the base layer first, utilizing its flatness and load-bearing capacity, and then tiles are laid with tile adhesive or cement mortar to form a beautiful and durable ground.5、Interior decoration: Carbon crystal board and Great Wall board are used for the wall. Carbon crystal board is waterproof, moisture-proof, fireproof and antibacterial, with flat surface and rich colors; the Great Wall Board is unique and decorative. The ceiling is made of light steel keel and bamboo wood fiber board. Light steel keel has high strength, light weight, good fire prevention and convenient installation; bamboo fiber board is made of natural bamboo fiber, which is environmentally friendly, sound-absorbing, heat-insulating and moisture-proof, and it is matched with light steel keel to create a comfortable ceiling space.

Factory

Customer Visit

Custom Style Prefabricated Building House

Building structure:

Prefabricated Building - Prefabricated House

Application:

Residential house

Vacation house

People Living

Business

Hotel

Keyword:

WHY CHOOSE US

Experience

20 Years of production customization experience

OEM/ODM

Support OEM/ODM customization

Reliable Quality

Strict quality inspection, careful selection of materials.

Certification

Obtained the certification of many authoritative organizations

Export

Advanced equipment and technology have been recognized

Customer Reviews

Suitable for a variety of scenarios such as modular barracks, refugee camps, site project departments, hotels, etc., each style is available in a wide selection of sizes and flexible configuration options.

Bryan White

Very in line with my expectations, no damage, very satisfied!

Olivia

All those little details went in with the assistance of Xindian Construction and we’re very grateful for their time and help in this project!

Edwin Wachsler

They are sending me replacements for the broken items even though I didnt have insurance. I will use them again and recommend anyone who wants good quality and service to use them.