- Product Details

-

Product Introduction

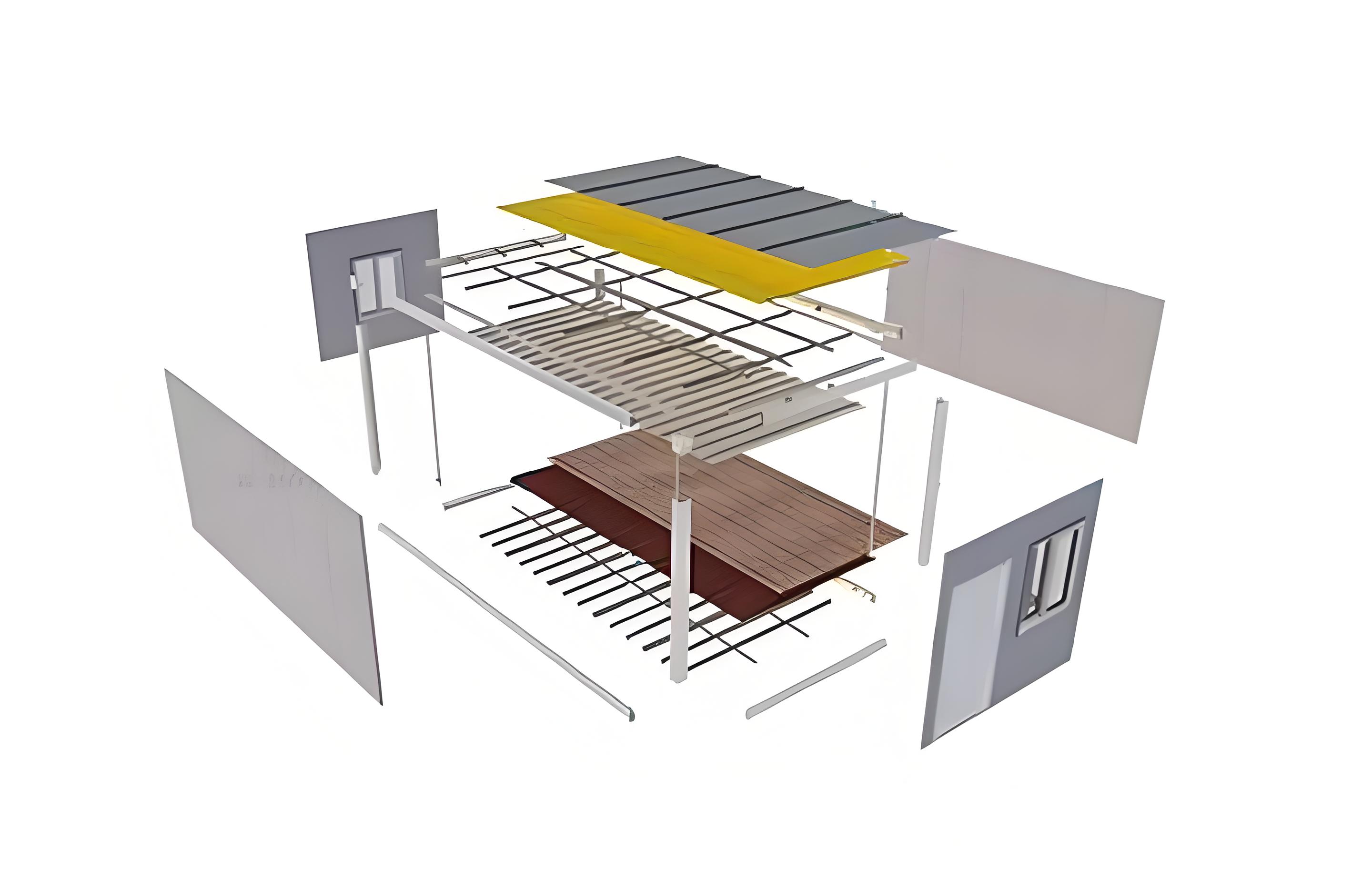

Components assembly modular house is composed of columns and top and bottom beams connected by fastening screws, while the columns and top and bottom heads are connected by carriage bolts. This design makes it easy to assemble and disassemble quickly while maintaining structural strength. All the materials of the components assembly modular houses are integrated and modularized, featuring uniform specification and appearance.

Parameter Table

Packing container house materials distribution list Basic Features External dimensions (L*W*H) Inner size (L*W*H) 2800*5800*2550 weight 1200KG container loading quantity A 40-foot cabinet

can hold 15 setsFramework

componentstand column beam corner fittings hexagon socket bolt glue cushion Auxiliary part Bottom bolt Bottom purlin 50 downspouts Top square tube Maintenance part Outer top tile thermal insulation cotton moisture sealer 1.8 glass magnesium plate Double sided 04 steel door Plastic steel single sliding window Bottom edge of column (with fastener) 0.3mm color steel 831 ceiling angle iron 50 reverse water tank self-drilling screw weather proofing sealant、polystyrene foam 950 type 50mm thick rock wool composite wall panel, iron sheet 0.3mm rock wool bulk weight 50kg Electrical

distributionDistribution box, 2P circuit breaker,Leakage protector, switch,LED light,

three-hole air conditioning socket,Five-hole socket, access line 4 square,Socket cable, light cableExplosion Diagram Display

Install Packaged Container Houses

The difference between Components Assembly Modular House and Flat Packed Modular House

- First, the difference of structural connection method

Components Assembly Modular House :

Columns and top and bottom beams are connected by fastening screws.

Column and upper and lower head connection using carriage bolts, this bolt has a certain thickness.

Flat Packed Modular House:

The columns and top and bottom beams are connected by welding, so the bolts are not visible on the outside.

Column and upper and lower head are connected with hexagonal bolts, and the bolts cannot be seen on the appearance.

- Second, the appearance and neatness of the difference

Components Assembly Modular House :

Due to the thickness of carriage bolts, there may be gaps when two boxes are placed side by side, affecting the overall neatness.

Flat Packed Modular House:

Due to the hidden design of hexagonal bolts, the two boxes will be very neat when placed side by side, and the appearance is more beautiful.

- Third, the difference of drainage function

Components Assembly Modular House :

When it rains, the water can be discharged through the water holes around the top of the box.

Flat Packed Modular House:

Built-in downpipe, water can be drained through the roof beam drain from the four built-in downpipes directly to the bottom of the box, improving the leakage of the house hidden danger.

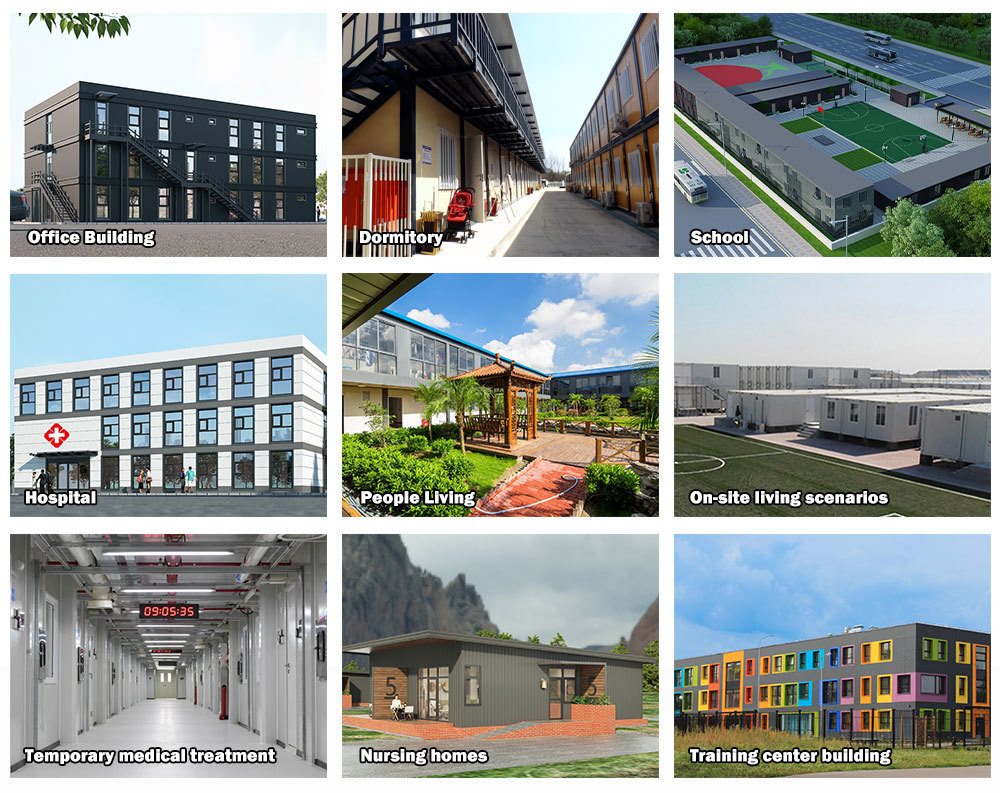

Application Scenarios

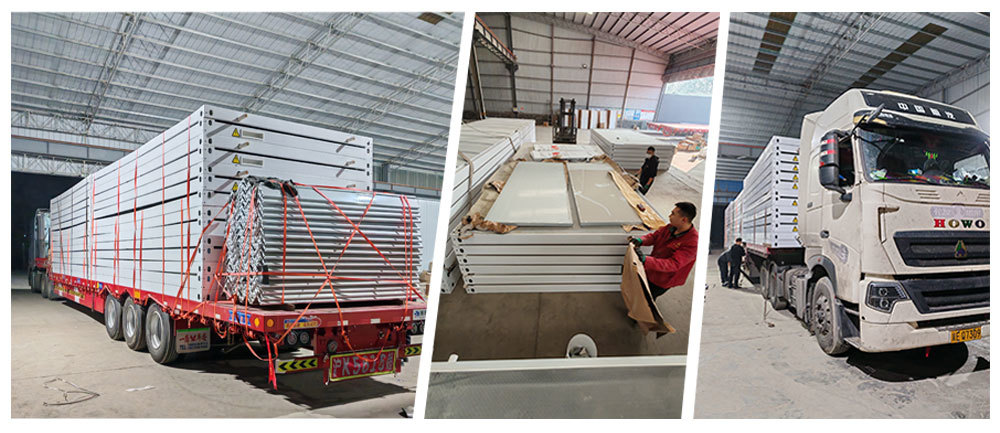

Delivery

- First, the difference of structural connection method

Factory

Customer Visit

Components Assembly Modular House

Modular Construction - Components Assembly Modular House

Office building

People Living

Hotel

Dormitory

School

Hospital

Dining Hall

On-site living scenarios

Keyword:

WHY CHOOSE US

Experience

20 Years of production customization experience

OEM/ODM

Support OEM/ODM customization

Reliable Quality

Strict quality inspection, careful selection of materials.

Certification

Obtained the certification of many authoritative organizations

Export

Advanced equipment and technology have been recognized

Customer Reviews

Suitable for a variety of scenarios such as modular barracks, refugee camps, site project departments, hotels, etc., each style is available in a wide selection of sizes and flexible configuration options.

Bryan White

Very in line with my expectations, no damage, very satisfied!

Olivia

All those little details went in with the assistance of Xindian Construction and we’re very grateful for their time and help in this project!

Edwin Wachsler

They are sending me replacements for the broken items even though I didnt have insurance. I will use them again and recommend anyone who wants good quality and service to use them.